Our ceramic coating is highly effective when used on engine exhaust system components including exhaust manifolds exhaust headers cat boxes turbochargers and tailpipes helping to protect sensitive components from the effects of heat.

Diy exhaust manifold ceramic coating.

Zybar heat dissipation technology increases horsepower torque by improved scavenging reduces radiant heat over 90 and reduces under hood temperatures.

There are a variety of reasons for coating an exhaust manifold header.

Remember that there are estimates.

The price really depends on the version of your exhaust manifold each part needs a process before applying the ceramic coating.

In other words ceramic coated headers look and function the same on mile one as they do on mile 300 000.

So the prices can be around 40 to 250 or more.

Our standard manifold and header paints are rated for up to 1 400 degrees and come in gray silver and black colors.

This technique has been adapted by many motorsport competitors and is commonly used on any part that will experience high temperatures.

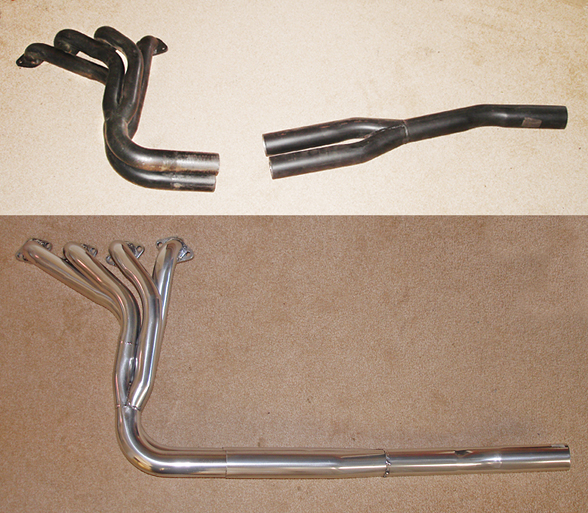

Exhaust manifolds can either be a cast iron factory type manifold or a tube steel header typically used in performance applications though they are becoming very common in oem applications.

Ceramic coating is fantastic as a heat insulator and will reduce the surface temperature within the exhaust by up to a third.

Exhaust manifold ceramic coating cost.

Use eastwood high temp exhaust coatings on your vehicle to provide protection in extreme conditions.

A ceramic header coating also provides protection against the corrosive materials in the exhaust.

This in turn will mean cooler intake temperatures and more power.

Ceramic has high resistance and is very durable.

Ceramic is a highly durable substance that resists corrosion and stands up to a large amount of abuse.