Depending upon the actual temperatures and stresses experienced by the coating a significant elastic modulus gradient will develop and evolve with time under high heat flux conditions.

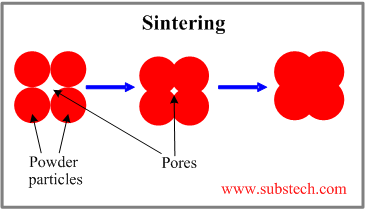

Densification process of ceramics.

Like traditional ceramics advanced ceramics are densified from powders by applying heat a process known as sintering.

High entropy diboride powdered products exhibited ultra fine particle size 0 5 μm after borothermal.

Some general points to remember about different types of firing end products.

Get ceramic pieces appropriate for the selected application.

The liquid phase sintering process of α sialon ceramics has been investigated by high temperature dilatometry and microstructural observation.

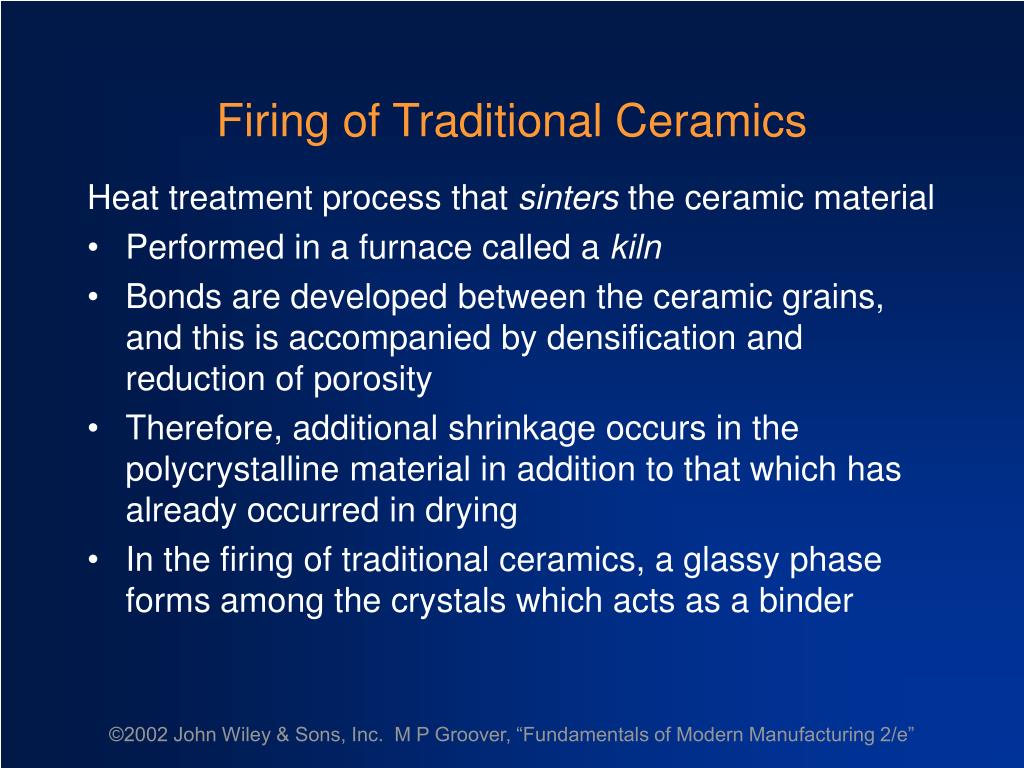

Unlike traditional ceramics however advanced powders are not bonded by the particle dissolving action of glassy liquids that appear at high temperatures.

Source krell et al 8.

Usually this is done by a sintering process which is a consolidation and densification step of the granular compact through the action of heat.

Figure 1 sintered powder and microstructure.

Doyun lee jung a lee young woo heo joon hyung lee jae il jung jeong joo kim the effect of yttrium nitrate addition on the densification behaviour of y2o3 ceramics during the cold sintering process journal of the european ceramic society 10 1016 j jeurceramsoc 2020 02 025 2020.

High entropy boride ceramics of zr 0 2 ta 0 2 ti 0 2 nb 0 2 hf 0 2 b 2 and zr 0 2 w 0 2 ti 0 2 mo 0 2 hf 0 2 b 2 were prepared by combining powder synthesis via borothermal reduction process at 1600 c and subsequent ceramic densification by spark plasma sintering at 2000 c in argon.

Firing also known as sintering or densification the ceramics pass through a controlled heat process where the oxides are consolidated into a dense cohesive body made up of uniform grain.

In addition isothermal shrinkage measurements have been performed to examine the densification kinetic parameter.

The sintering densification process also results in an increase in the elastic modulus of the porous ceramic coating at high temperatures.

Advanced ceramics advanced ceramics densification.

The driving force of sintering process is reduction of surface energy of the particles caused by decreasing their vapour solid interfaces.

Ceramics as is pointed out in the article ceramic composition and properties are traditionally described as inorganic nonmetallic solids that are prepared from powdered materials are fabricated into products through the application of heat and display.

Chen in thermal barrier coatings 2011.

Instead solid state sintering predominates.

Sintering or frittage is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction.

During this stage the microstructure of the samples evolves see figure 1.